Bogie Hearth Furnace

(MASS ENGINEERS)

Bogie Hearth Furnace

Mass Engineers is one of the Bogie Hearth Furnace Manufacturers in Maharashtra. Latest, Strong, Sturdy, PLC Controlled Heating Quenching Technology by Mass Engineers MN Steel Hardening, SS Solution Treatment, Forging, Quenching, Tempering & Normalizing. Also available for PWHT (Post Weld Heat Treatment) In Gas Fired Bogie Hearth Heating Process we use Burners for firing using LPG/Natural Gas/Bio Gas or oil Diesel/Furnace oil/Petroleum oils Gas-fired heating furnaces have a burner in the furnace fuelled by gas or oil.

As a leading Bogie Hearth Furnace Manufacturer in Miraj. A blower forces cold air through a heat exchanger and then through ductwork that distributes the hot air through the hole furnace over on the material of treatment for cycle hours then after the process completion it will cool via a fan or in the normal surrounding temperature. Gas Fired Furnace are fired with high-efficiency burners supported by a full complement of combustion systems consisting of a combustion fan, atomizing fan, oil heating and pumping systems, and/or gas trains. In addition, auto ignition, flame failure safety, and complete control systems are offered.

As one of the best Bogie Hearth Furnace Suppliers and Exporters from India. The gas train incorporates all the gauges, safety switches & ratio controllers. Practically any type of liquid or gaseous fuel can be used viz. Furnace Oil, Light Diesel Oil, LPG Natural Gas singly or a combination of any oil or gas in case of dual fired furnaces. To improve fuel efficiency, Recuperates for heating combustion air up to 500°C will be provided. For customers requiring even more fuel efficiency, Regenerative burners can be offered that can give an air preheat of 1000°C or more.

Features And Specifications of Fired heat treatment furnaces.

• Strong sturdy structure with good quality MS material with superior design and skilled workers.

• Temperature Range – Upto 1225 °C (as per given data by clients)

• Batch capacity upto 200 MT. (As per requirement of clients)

• Type of Furnace: Chamber, Bogie, Continuous and Batch type

• Robust Heavy Duty construction and highly fuel-efficient.

• Lined with high-density ceramic fiber modules and blankets, the furnace delivers high fuel efficiency.

• Variants include Dual fuel (Oil & Gas), Oil (LDO/HSD) and Gas (PNG/LPG), Blast Gas

• Fully automatic operation with auto ignition and flame monitoring system.

• Sealing of the vertical lift doors and bogie through pneumatically operated soft seal clamps to ensure no ingress of cold air.

• Thermal calibration as per API standards norms.

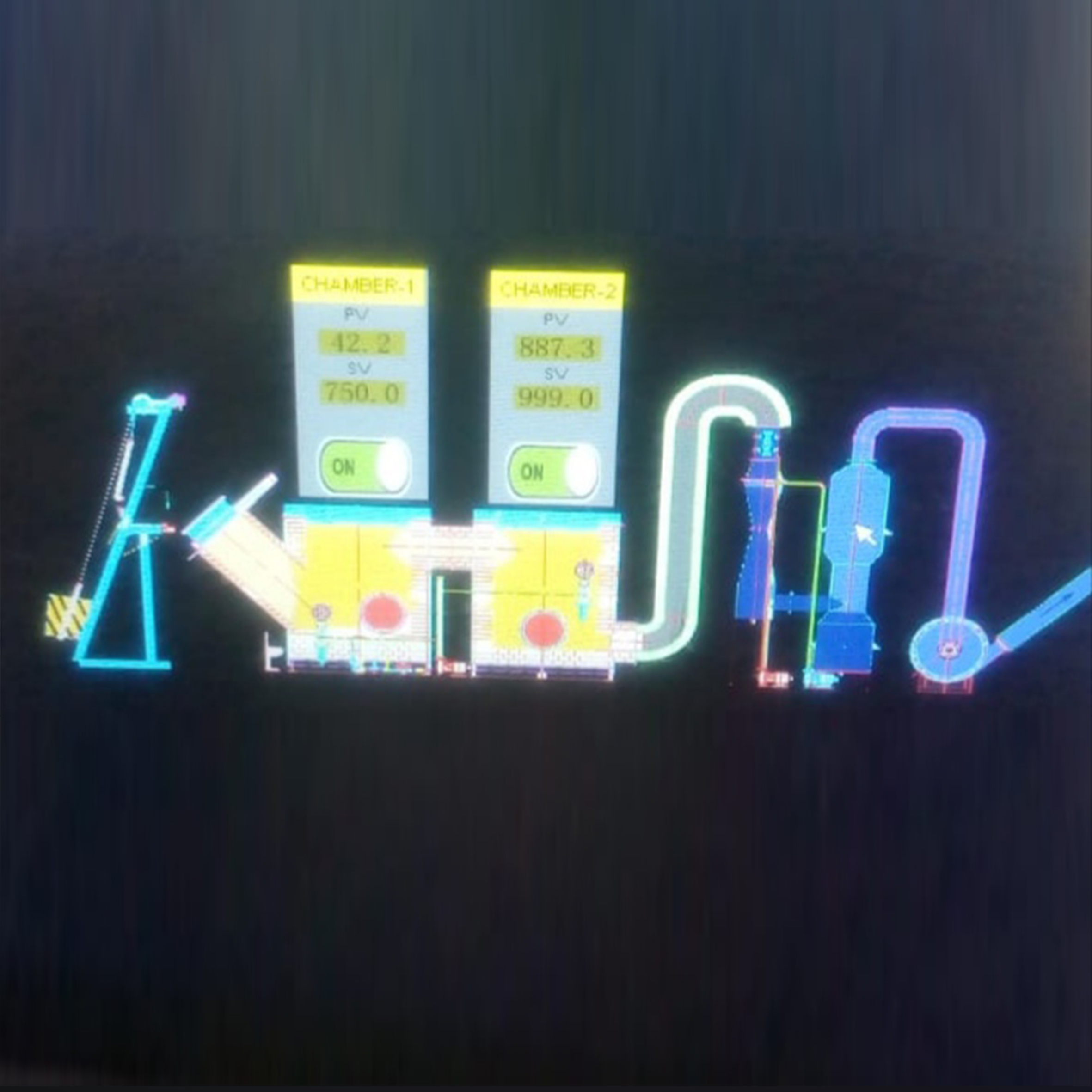

• User-friendly, PLC-based burner management system supported by SCADA system with HMI interface.

• Super sealing lining with Ceramic fiber blankets and boards with specifications of temperature up to 1400 deg c temperature.

Applications:

- Annealing

- Normalising

- Hardening

- Solution Treatment Heating

- Forge Heating

- Tempering

- Aluminium Solutions sing

- Stress Relieving

- Ductile Iron Full Annealing

- ADI (Austempered Ductile Iron)

- mass@massengrs.com Furnace Enquiry Contact Number :

- +91-8329230101 , +91-9225819420 Mass Purchase Department Number:

- +91-9284009411 , +91-9356421131

-

Plot No 82 MIRAJ MIDC, Miraj Maharashtra, 416410 INDIA